Visiontek Systems Ltd.

Glass for Electronic & Industrial Applications

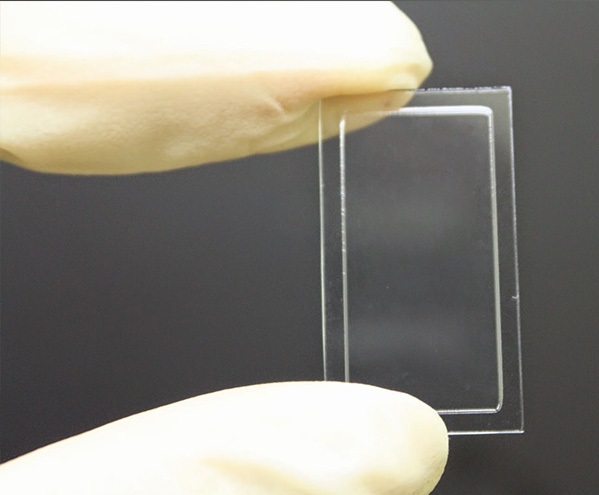

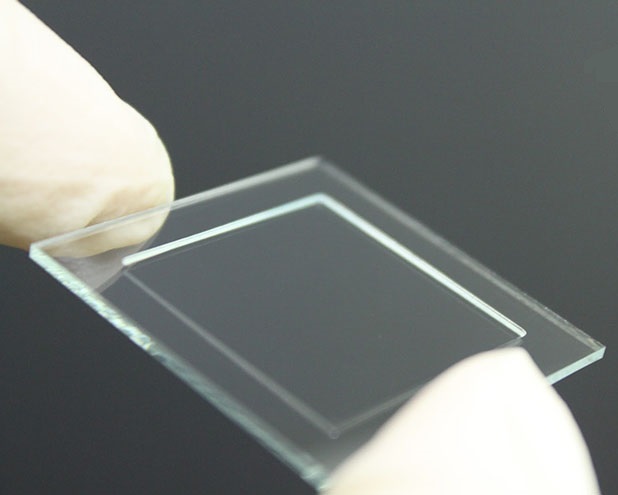

Encapsulation Glass Customised Soda Lime Glass

Visiontek Systems offers a range of customised encapsulation glass using soda lime float glass

Encapsulation using soda lime glass is a method of enclosing something like stained glass or micro-particles, in a layer of this common, affordable glass to protect it. Soda lime glass is frequently used for this purpose because it is cost effective, easy to cut and shape, and offers good optical clarity

The thickness of these glasses can be 1.1mm or 0.7mm. and the depth of the groove can be 0.3mm or 0.5mm. If we use 1.1mm glass, the depth of groove can be 0.3mm or 0.5mm. for 0.7mm glass, the depth of groove will be 0.3mm only. The size of glass can be the designed from customer requirements

We can process customised encapsulation glass for OLED / LED encapsulation.

Please provide your glass design with all dimensions and we will make the glass according to your design

Encapsulation is the process of surrounding or enclosing something in a protective layer. The soda lime glass acts as a barrier to protect the encapsulated material from the external environment, such as moisture, air, or physical impact

Examples and Applications are as follows

NUCLEAR WASTE - Soda lime silicate glass is being studied for encapsulating simulant nuclear waste, such as TRISO particles, to create a durable composite that can be stored safely

NANOMATERIALS - Researchers use soda lime glass to encapsulate materials like gold nano-particles to study their properties or to create novel composites

GENERAL PROTECTION - In some industrial applications, soda lime glass is used as a protective cover for sensitive components because it is a cost effective way to add protection without a significant increase in cost

VisionTek Systems Ltd.

1 The Acorns

Upton

Chester

Cheshire CH2 1JL

United Kingdom

Tel : 44 (0) 1244 370203

e-mail: visiontek.sales@gmail.com